What is the application scope of BGA Gold Finger Blue Solder Mask PCB?

2025-06-05

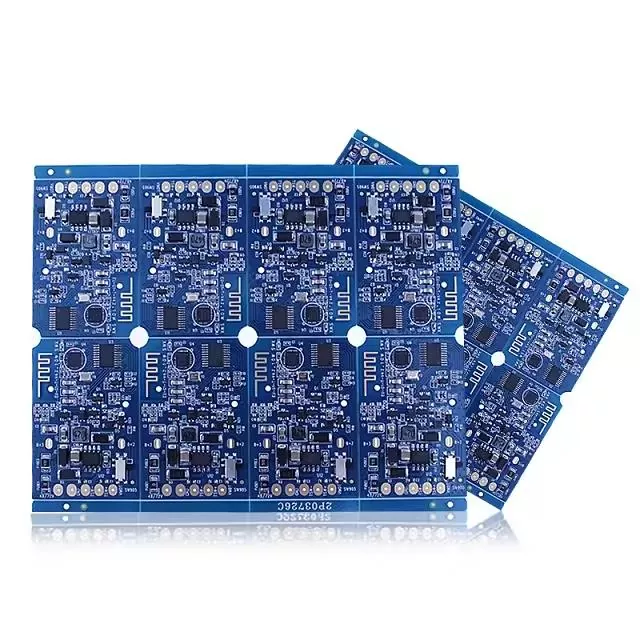

BGA Gold Finger Blue Solder Mask PCB plays a vital role in modern high-density electronic design. This type of circuit board with special process is widely used in cutting-edge equipment with strict requirements on connection density, signal integrity and long-term reliability due to its unique structural performance.

The core advantage of BGA Gold Finger Blue Solder Mask PCB lies in its precise ball grid array packaging and edge high conductivity gold-plated contact points, combined with the highly visually recognizable blue solder mask layer, which provides a solid foundation for the stable operation of complex circuits. In the field of high-performance computing, such as data center servers, high-end graphics cards and artificial intelligence acceleration cards, BGA Gold Finger Blue Solder Mask PCB is the key carrier for realizing multi-chip high-speed interconnection and processing massive data. Its optimized electrical performance and solid gold fingers ensure the purity and stability of high-frequency signal transmission.

Industrial automation control systems also benefit from this technology, especially in harsh factory environments, where control core boards, motion controllers and high-speed communication modules generally use BGA Gold Finger Blue Solder Mask PCB. Its blue solder mask layer not only has excellent anti-solder bridge capability to prevent accidental short circuits between dense solder joints, but also effectively resists the penetration and erosion of solder spatter and flux in the production environment. The inherent high integration density and anti-interference characteristics of BGA gold finger blue solder mask PCB make it the only choice for building complex industrial control systems.

In addition, in high-end network communication equipment such as core routers, switches and 5G base stations, BGA gold finger blue solder mask PCB is the core hardware platform for achieving high-speed backplane connection and carrying ultra-large bandwidth communication. Its gold finger part ensures reliable contact and low-loss transmission for repeated plugging and unplugging, while the blue solder mask layer improves weather resistance in long-term operation and recognizability after maintenance. The precision control and image processing units of medical imaging equipment such as CT and MRI also rely on the excellent accuracy and stability of BGA gold finger blue solder mask PCB to ensure the accuracy of medical diagnostic data. In summary, BGA gold finger blue solder mask PCB is the basic hardware guarantee to support the information technology revolution and promote high-end manufacturing and cutting-edge medical progress.