How can printed board assembly reduce board waste through reasonable panelization?

2025-06-20

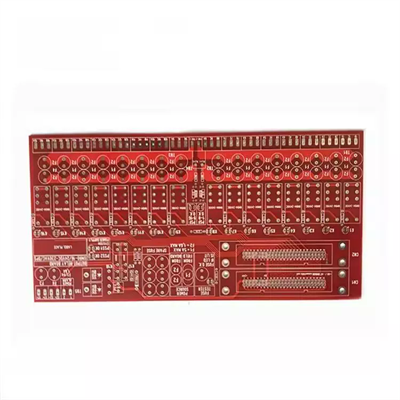

In the production process of printed board assembly, board waste directly affects cost and environmental benefits. Through careful panelization design, manufacturers can significantly improve board utilization. The core of panelization is to arrange multiple printed circuit board units as closely as possible on a standard-sized substrate to maximize the use of effective area and reduce waste at the edges and connections. Design engineers need to comprehensively consider the shape of the circuit board, process requirements (such as the spacing required for V-grooves or stamp hole separation methods) and the standard size of the substrate, and reasonably plan the arrangement method (such as yin-yang, rotation or mixed) to fill the blank area. For example, cleverly integrating special-shaped units with complementary sizes can effectively fill the gaps created by traditional rectangular panels.

In the printed board assembly process, optimizing panelization not only means direct savings in raw material costs, but also indirectly improves overall efficiency. Tight panelization design means more units are produced on a single substrate, reducing the number of production batches, thereby reducing the time and energy consumption required for frequent equipment settings, multiple loading and subsequent panel separation. This requires close collaboration between designers, engineering departments and production departments to accurately calculate the cutting path, process edge width and positioning hole position during layout, ensuring that the clamping and positioning requirements of subsequent assembly equipment are met without taking up too much extra space.

Ultimately, an efficient panelization strategy is a key means to achieve green manufacturing and cost control for printed circuit board assembly. It requires a deep understanding of material properties, equipment limits and production processes, and through refined layout calculations and simulations, the scraps generated by substrate cutting are minimized while ensuring unit quality and smooth separation. Continuously optimizing the panelization solution is an inevitable choice for printed board assembly manufacturers to enhance their competitiveness and practice sustainable development, and effectively respond to resource constraints and cost pressures by "making the best use of everything".